Freeze-dried eye mask is an eye skin care product made using freeze-drying technology. This technology is favored by consumers in the cosmetics industry with its unique advantages of rapidly freezing the active ingredient into a solid state and then removing the moisture under vacuum conditions, preserving the biological activity and effectiveness of the ingredients. Of course, the production of freeze-dried eye masks is inseparable from the great help of pharmaceutical lyophilizers.

Freeze-dried eye masks are effective in improving eye skin problems due to their rich hyaluronic acid, collagen, vitamin C, peptides and plant extracts. The significant advantage of lyophilization over traditional methods is the ability to effectively lock in these active ingredients and maintain their stability and activity until they are dissolved. After the lyophilizer freeze-dries the active ingredient to a quiescent state, the unstable ingredient retains its effectiveness and stability during storage and use, thus improving the overall effectiveness of the product.

Lyophilization Process

1.Raw Material Preparation: Select suitable active ingredients, such as hyaluronic acid, collagen, vitamin C, peptides, etc. These ingredients are formulated into a solution in specific proportions, ensuring adequate mixing and even distribution.

2.Preparation of the Mold: Injection molding or pressing process is usually used to make a mold suitable for the shape of the eye mask. The surface of the mold is required to be smooth and free of impurities to ensure the quality of the eye mask.

3.Coating Solution: The mixed active ingredient solution is evenly applied to the surface of the mold, ensuring an even distribution of components for each eye mask.

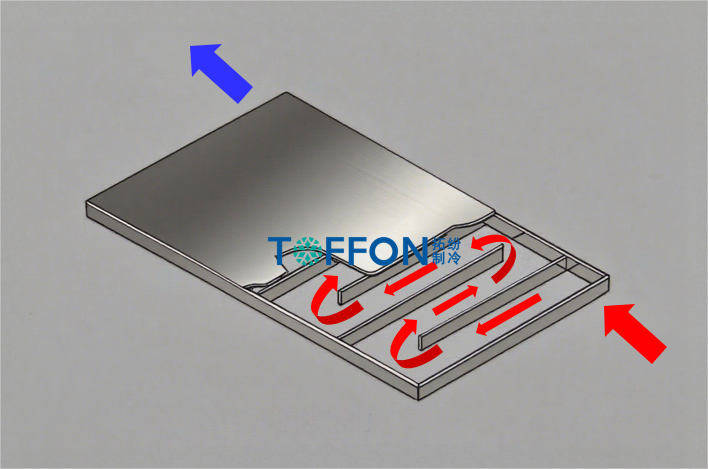

4.Freezing Step: The coated mold is placed in an ultra-low temperature freezing equipment and quickly frozen to form a solid solution. In this process, the temperature and time need to be strictly controlled to protect the activity of the ingredients.

5.Lyophilization Step: The frozen eye mask mold is transferred to the lyophilization equipment. Generally, pharmaceutical lyophilizers or pilot freeze dryers are used, which are more stable and temperature-controlled than small freeze dryers or food freeze dryers, and are more suitable for the production of high-demand products. Pharmaceutical lyophilizers provide a vacuum environment to gradually remove the solid moisture in the eye mask, so that the solid moisture is directly sublimated into a gaseous state, avoiding the damage caused by high-temperature evaporation of the active ingredient, thereby retaining the effect of the active ingredient to the greatest extent.

6.Packaging Steps: The lyophilized eye mask is gently removed from the mold and sterilely packaged to ensure it is not contaminated before use. The removal of moisture makes the freeze-dried eye mask less susceptible to deterioration in a dry state and can be stored for a long time without the need to add additional preservatives.

CN

CN English

English